CNC software plays a crucial role in the world of manufacturing and machining, enabling precise control over machinery and tools. As technology continues to evolve, the importance of selecting the right CNC software becomes increasingly apparent. This article will explore the various types of CNC software available, their features, and how they can enhance your machining processes, making it an essential read for anyone in the industry.

In today’s competitive landscape, having the best CNC software can significantly impact your efficiency and output quality. With options ranging from CAD (Computer-Aided Design) software to CAM (Computer-Aided Manufacturing) software, understanding the differences and applications of each is vital for making informed decisions. This comprehensive guide will take you through the essentials of CNC software, helping you choose the right tools for your specific needs.

Whether you are a seasoned machinist or just starting in the field, this article will provide valuable insights into CNC software, ensuring you have the information needed to optimize your operations. From understanding the basic functionalities to exploring advanced features, you will gain a well-rounded understanding of CNC software and its importance in modern machining.

Table of Contents

- What is CNC Software?

- The Importance of CNC Software

- Types of CNC Software

- Key Features to Consider

- Top CNC Software in the Market

- How to Choose the Right CNC Software

- Case Studies: Real-World Applications

- The Future of CNC Software

What is CNC Software?

CNC software refers to the programs used to control CNC machines, which automate the process of manufacturing parts and components. These machines can include mills, lathes, routers, and more, all of which require specific instructions to operate accurately. CNC software translates design files into machine language, allowing for precise movement and operation of the tools.

Understanding CNC Programming

CNC programming is the process of writing instructions that tell the CNC machine how to move, what speed to use, and what paths to follow. This programming typically involves G-code, a language that provides commands to the machine. Understanding how to write and modify G-code is essential for maximizing the potential of CNC software.

The Importance of CNC Software

Choosing the right CNC software can have a profound impact on your manufacturing process. Below are several reasons highlighting its importance:

- Precision: CNC software ensures high accuracy in machining, allowing for the production of complex shapes and designs.

- Efficiency: Automated processes reduce time spent on manual adjustments and increase overall productivity.

- Cost-Effectiveness: By minimizing waste and errors, CNC software can lead to significant cost savings in the long term.

- Flexibility: Many CNC software solutions allow for easy modifications to designs, enabling quick adaptations to customer demands.

Types of CNC Software

There are various types of CNC software, each designed for specific functions within the machining process. The most common categories include:

1. CAD Software

Computer-Aided Design (CAD) software is used to create detailed 2D and 3D models of parts and products. Popular examples include AutoCAD and SolidWorks.

2. CAM Software

Computer-Aided Manufacturing (CAM) software translates CAD designs into machine instructions. It often includes features for toolpath generation and simulation. Examples include Mastercam and Fusion 360.

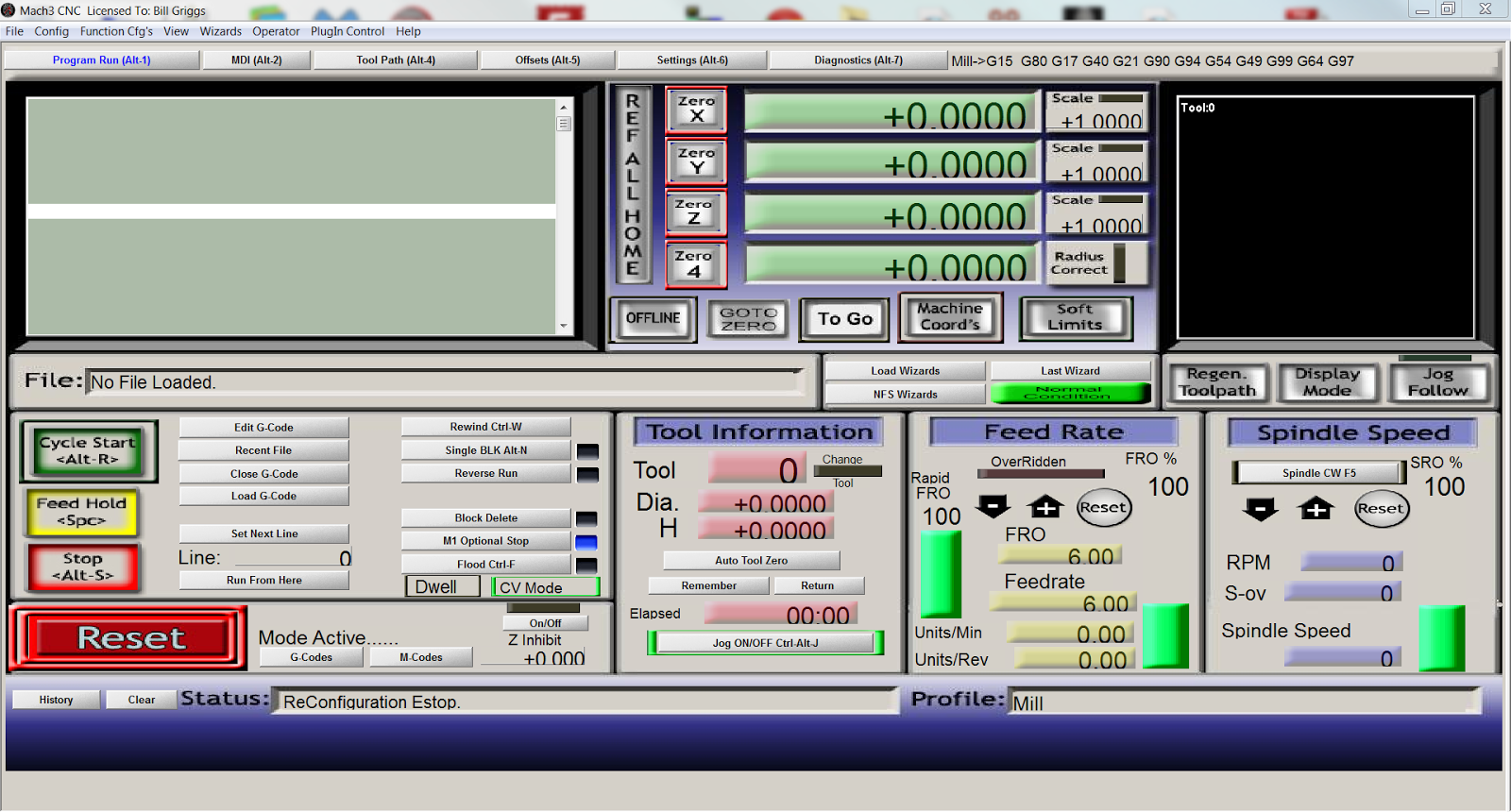

3. CNC Control Software

This software directly interfaces with CNC machines, providing real-time control over operations. Examples include Mach3 and LinuxCNC.

4. Simulation Software

Simulation software allows users to visualize machining processes before execution, helping to identify potential issues. Examples include Vericut and NCSimul.

Key Features to Consider

When choosing CNC software, it's essential to evaluate several key features that can enhance your machining operations:

- User Interface: An intuitive interface can significantly reduce the learning curve and improve workflow.

- Compatibility: Ensure the software is compatible with your CNC machines and other existing systems.

- Toolpath Generation: Efficient toolpath generation algorithms can optimize machining time and reduce wear on tools.

- Post-Processing: Look for software that supports various post-processors to ensure compatibility with different machines.

Top CNC Software in the Market

Here is a list of some of the most popular CNC software currently available:

| Software Name | Type | Key Features |

|---|---|---|

| Fusion 360 | CAD/CAM | Cloud-based, collaborative features, integrated simulation. |

| Mastercam | CAM | Advanced toolpath capabilities, strong community support. |

| SolidWorks | CAD | Robust modeling tools, extensive library of components. |

| Mach3 | CNC Control | User-friendly interface, supports various machine types. |

How to Choose the Right CNC Software

Selecting the right CNC software involves several steps:

- Assess Your Needs: Determine the specific requirements of your projects and operations.

- Research Options: Explore various software solutions, comparing features, pricing, and user reviews.

- Trial Versions: Take advantage of free trials to test the software in your environment.

- Consult Experts: Seek advice from industry professionals or forums to gain insights into the best options.

Case Studies: Real-World Applications

Exploring real-world applications of CNC software can provide valuable insights into its benefits:

Case Study 1: Aerospace Component Manufacturing

A leading aerospace manufacturer implemented advanced CAM software, resulting in a 30% reduction in production time and improved precision in complex component manufacturing.

Case Study 2: Custom Furniture Design

A custom furniture maker adopted a CAD/CAM integrated solution, enabling rapid prototyping and customization, leading to increased customer satisfaction and sales.

The Future of CNC Software

The future of CNC software is poised for significant advancements, including:

- Increased Automation: More sophisticated algorithms will enhance automation capabilities, reducing manual intervention.

- AI Integration: Artificial intelligence will play a larger role in optimizing machining processes and predicting maintenance needs.

- Cloud Computing: Cloud-based solutions will continue to rise, offering enhanced collaboration and data storage.

Conclusion

In conclusion, CNC software is an indispensable tool for modern manufacturing, providing precision, efficiency, and flexibility. By understanding the different types of software available and their key features, you can make informed decisions that will optimize your machining processes. We encourage you to explore the various options available and consider your specific needs to choose the right CNC software for your operations.

If you found this article helpful, please leave a comment, share it with your colleagues, or explore other informative articles on our site. Your engagement helps us create more valuable content for you.

Penutup

Thank you for taking the time to read our comprehensive guide on CNC software. We hope you found the information insightful and empowering. Remember to visit our site regularly for more updates and expert articles on CNC technology and manufacturing trends.